Logistics is one of the key drivers of growth in the German economy. With a projected industry revenue of around €331 billion in 2024, it is the third-largest sector of the German economy, according to the German Logistics Association (BVL). At the same time, companies are facing increasing complexity, a shortage of skilled workers, and pressure to improve efficiency. This is particularly evident in intralogistics, where processes take place in confined spaces and at high speed.

While goods flows are digitally tracked globally, the situation within companies often presents a different picture. Manual transport processes, paper-based order picking, and fragmented IT solutions dominate daily operations. The desire for automation is there. However, the path to achieving it remains unclear for many.

Why good ideas are often not implemented

Technically, much is already possible today. Driverless transport systems, picking robots, intelligent conveyor technology, and AI-based control solutions can significantly improve processes such as demand planning and route optimization. Not because the technology is lacking, but because of high initial investments, unclear amortization periods, and a lack of know-how. As a result, potential remains untapped due to fear of complexity, costs, and lengthy implementation.

How Low-Code Opens New Paths

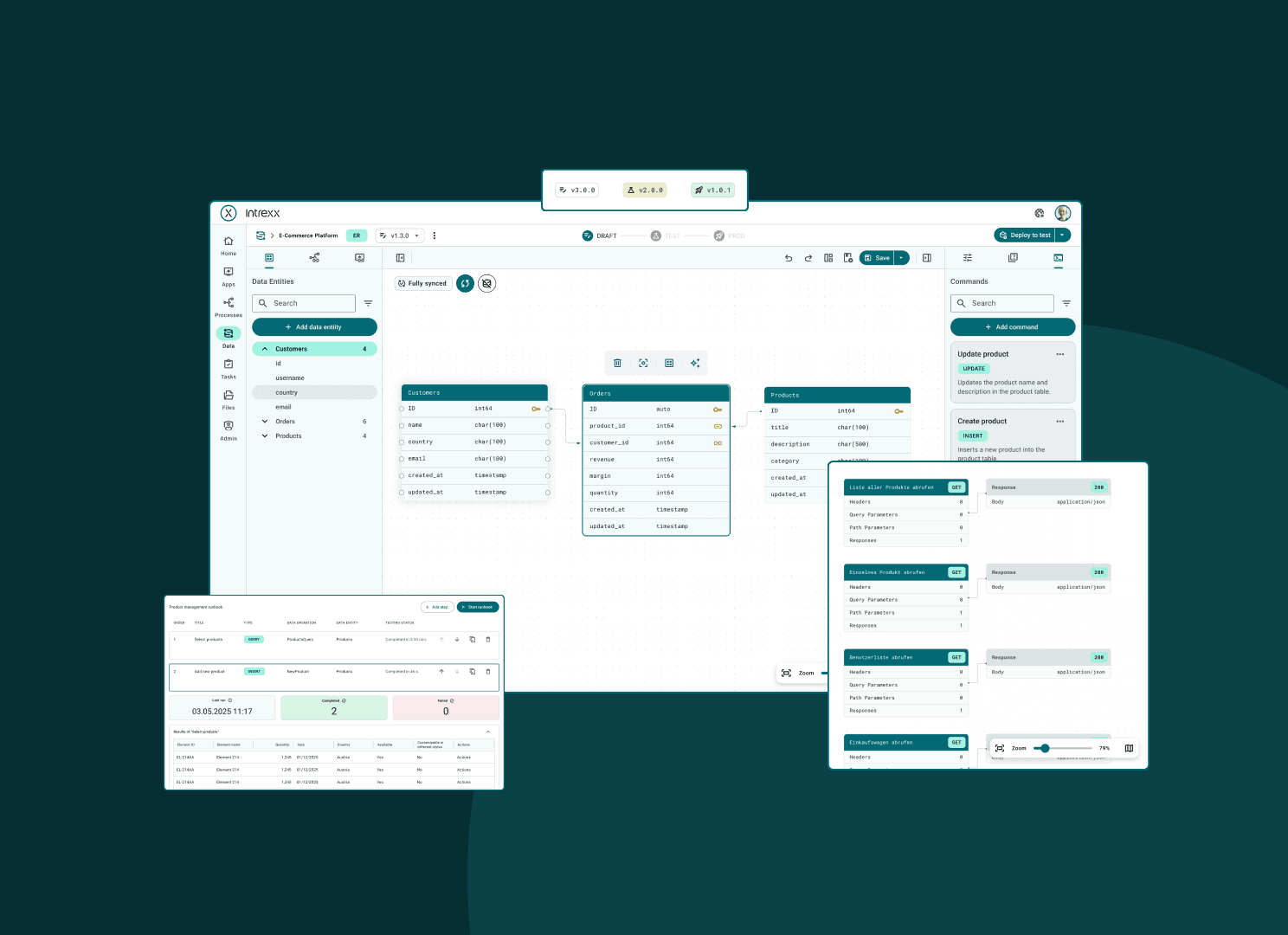

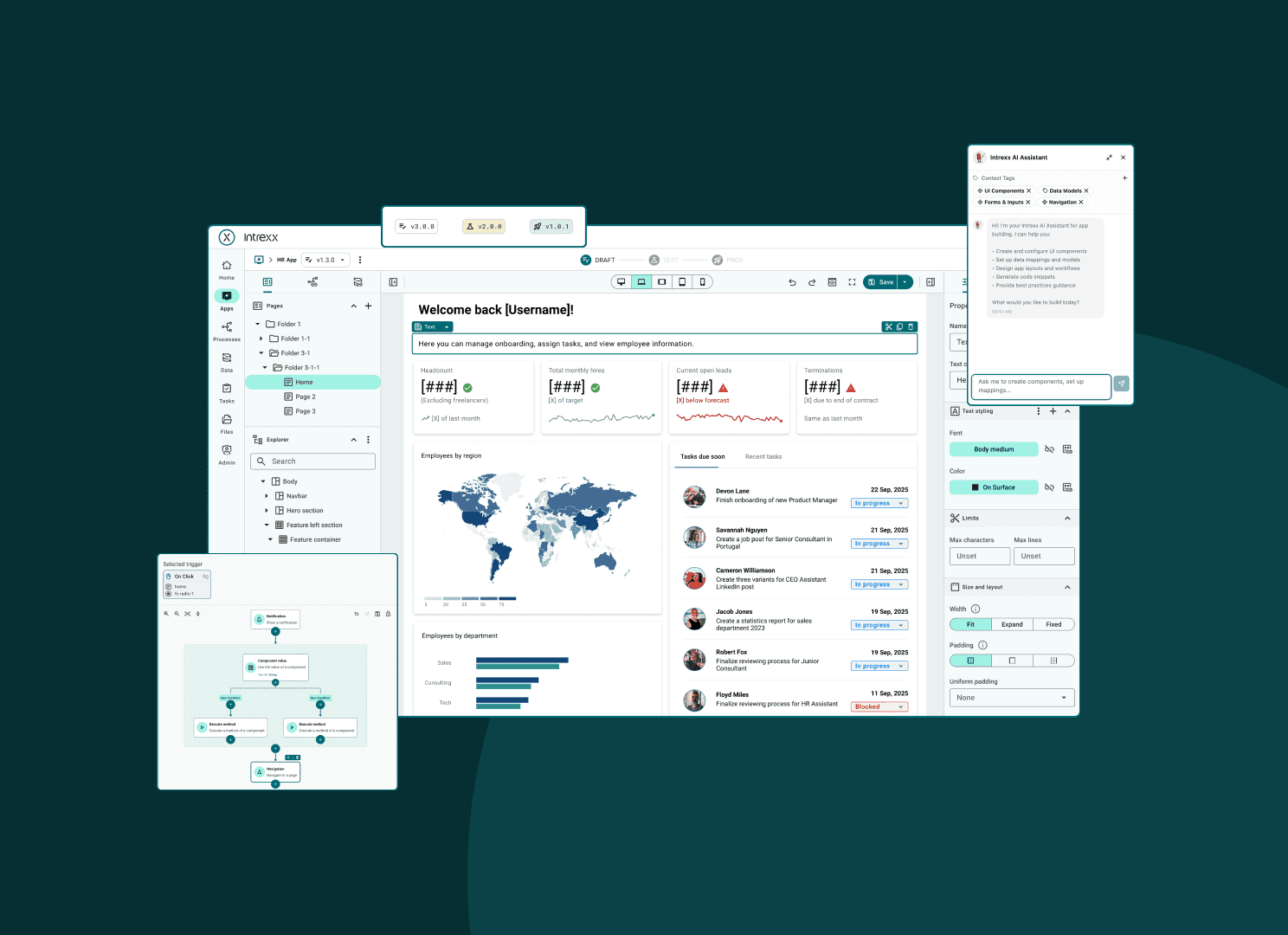

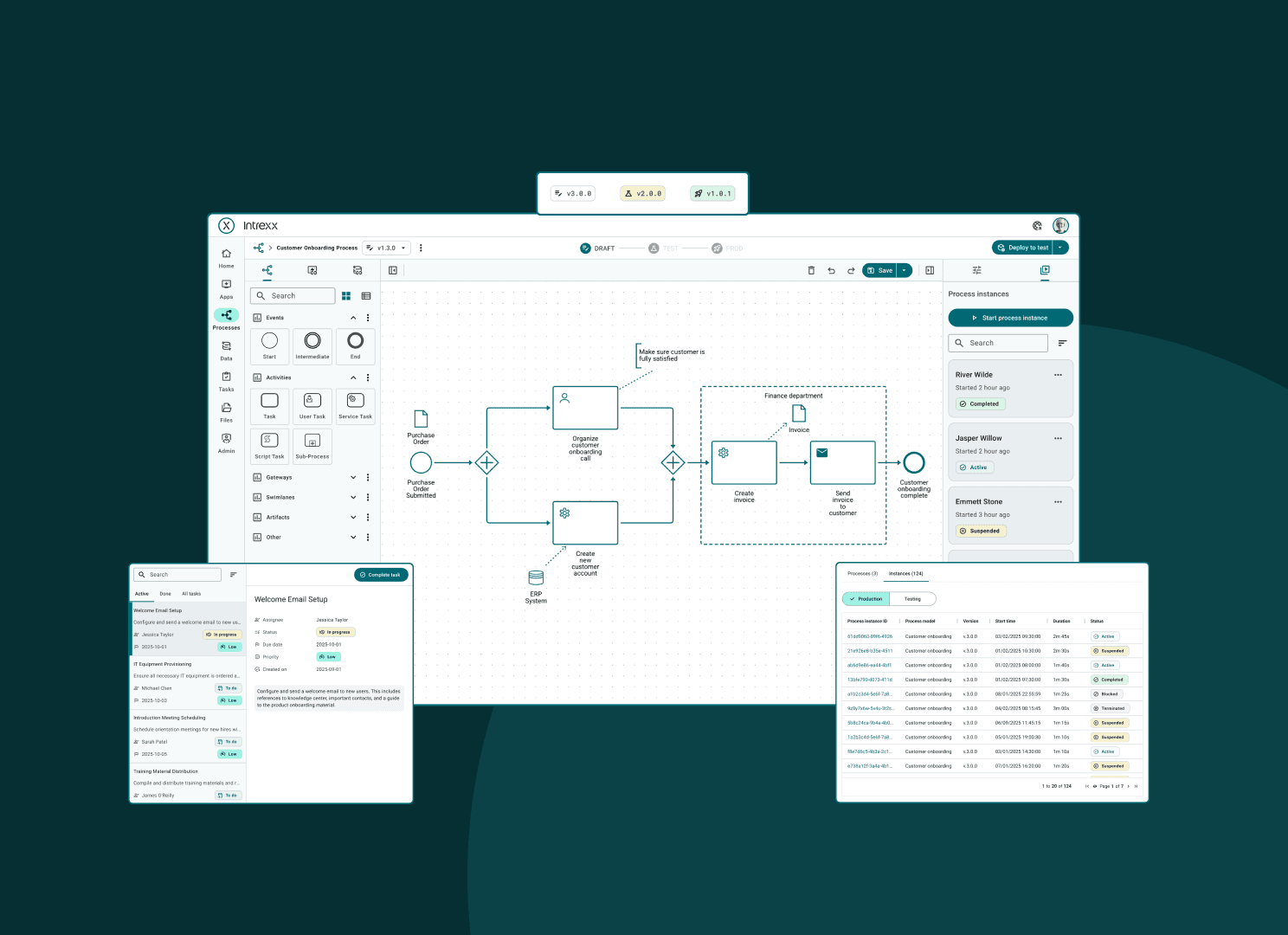

This is where low-code platforms come in. Companies can create their own applications, automate workflows, digitize processes step by step, and don't have to immediately overhaul their entire logistics. Unlike traditional standard software, which is often expensive and frequently doesn't communicate with other systems, low-code solutions allow for flexible process integration. Excel spreadsheets, isolated solutions, and data silos are reduced, and processes become transparent and efficient. With a low-code approach, intralogistics can be digitized agilely, step by step, automatically, cost-effectively, and tailored to specific requirements.

Pilot Projects as a Starting Point

To realize the advantages in practice, targeted pilot projects are a particularly good starting point, especially within existing structures. One example is internal goods transport. A medium-sized logistics company can easily digitize its intralogistics step by step.

In the first pilot phase, a low-code application is used to manage transport orders between goods receiving, the warehouse, and picking stations. Transport orders are digitally recorded, drivers receive optimized routes, and inventory levels are updated in real time. The results are quickly apparent: less manual coordination, shorter lead times, greater transparency, and a significant reduction in errors. Thanks to open, scalable interfaces, the system can be expanded modularly later.

In a second expansion phase, pick-by-light systems, semi-autonomous picking robots, or other automation solutions can be integrated without requiring any adjustments to existing processes. This creates a future-proof, flexible infrastructure that grows with the company's needs.

Targeted Analysis as a Foundation

Before implementing digital applications or automation solutions, a thorough analysis of existing processes is crucial. Where do bottlenecks occur, and which tasks are monotonous, error-prone, or particularly resource-intensive? Intralogistics often holds the greatest potential for efficiency gains. A systematic analysis process, ideally supported by external technology or consulting partners, helps to identify the optimal entry point, avoid misguided investments, and strategically align pilot projects.

It's worthwhile to look beyond individual locations. Digitalization only unfolds its full potential when processes are integrated across the entire value chain. Crucially, this depends on how well employees and partners are digitally integrated. Only with seamless, reliable data interfaces can goods flows be efficiently controlled in real time, processes be transparently mapped, and intralogistics be sustainably optimized. A thorough analysis thus lays the foundation for successful pilot projects, modular expansions, and long-term process automation.

Sustainable Intralogistics is Created Step by Step

The challenges of intralogistics cannot be solved with isolated technologies or short-term measures. A crucial approach is one that reduces complexity, considers existing structures, and creates demonstrably significant added value step by step. Low-code enables precisely this approach: processes are digitized where the benefits are immediately apparent, without overwhelming the entire organization. Companies that systematically analyze their intralogistics, strategically launch pilot projects, and modularly develop digital solutions lay the foundation for sustainable automation. The decisive factor is not speed, but the ability to react flexibly and continuously improve processes.